Virtually Eliminates Cross-Contamination

Temescal’s patented PopTop® e-beam sources offer enhanced convenience, reliability, and throughput in applications ranging from optical and microelectronic production to compound semiconductors and specialized R & D coatings. The key to these performance enhancements is Temescal’s pneumatically actuated “PopTop” crucible cover, which is raised automatically before turret rotation. The net benefit is the virtual elimination of cross-contamination.

Mounting

Models

- Temescal 3PT, rated up to 12kW

- Temescal 2PT, rated up to 10kW

Key Features

- Movable crucible cover, which rises before crucible is rotated

- Pneumatically driven, low-impact cover motion

- Lip of cover recessed around exposed pocket

- Raised structures on underside of cover interlock with crucible web walls

- Virtual elimination of cross-contamination

- Minimal deposition on web walls and on cover margins around exposed pocket

- Reduced risk of damage to source and turret indexer

- Removable/replaceable cover and crucible enable easy source convertibility

- Enhanced crucible cooling improves thermal stability during evaporation

- Adjustable internal and external pole piece extensions optimize beam spot control, regardless of beam position

- Ultra-stable magnetics eliminate the need to regauss magnetic parts following source disassembly

- Power ratings: 1-10 kW (Model 2PT) and 1-12 kW (Model 3PT)

Understanding The Benefits of Temescal’s PopTop source Design

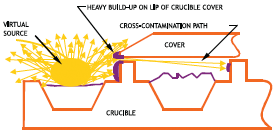

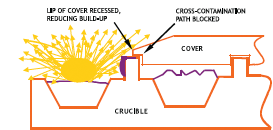

The diagrams below illustrate how the design of the PopTop cover eliminates cross-contamination and reduces deposition on the lip of the cover around the exposed pocket.

Cross-Contamination Path in Conventional Turret Source

Temescal PopTop source: Interlocking Cover Blocks Cross-Contamination Path

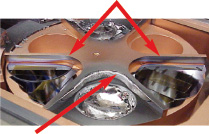

In the photos below, the conventional turret sources show clear evidence of cross-contamination, while the turret in the PopTop source shows none.

Conventional Turret Source

Shadows indicating cross-contamination on walls of adjacent pockets

Temescal PopTop Source

Pockets from which material was evaporated

Heavy build-up on wall of pocket from which material was evaporated

No evidence of cross-contamination on walls of adjacent pocket

As the following photographs show, the design of the PopTop gun s cover also reduces deposition along the lip ofthe cover around the exposed pocket.

Conventional turret source. Heavy build-up of material deposited on lip of cover is fused with build-up on crucible web wall. Result: High risk of turret jamming.

Temescal PopTop source. Build-upon lip of crucible cover greatly reduced. Risk of jamming eliminated.

Temescal Model 2PT and 3PT ‘PopTop’ SuperSources

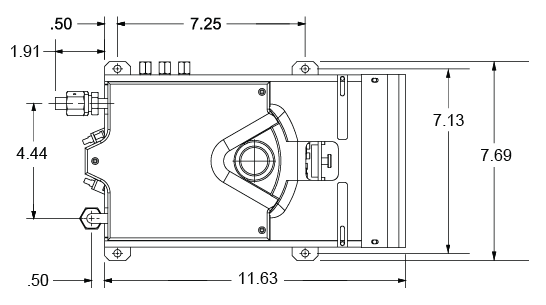

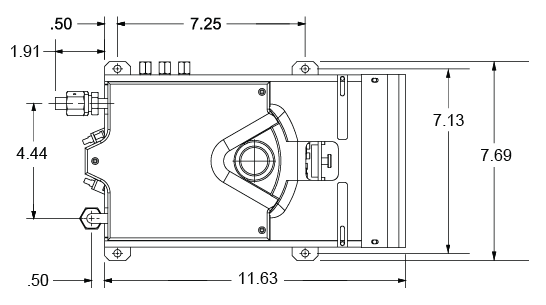

| Dimensions | ||

|---|---|---|

| Dimensions | Refer to Drawings | |

| Weight | Model 2PT: 44.2 lbs. (20 kg) | |

| Model 3PT: 50.3 lbs. (22.8 kg) | ||

| Rotation torque | 10 in.o lbs. (11.5 kg o cm) | |

| Max. bakeout temp. | 302° F (150° C) | |

| Max. power | Model 2PT: 10 kW | |

| Model 3PT: 12 kW | ||

| Acceleration voltage | 4–10 kV | |

| Operating pressure | ||

| Maximum | 5 x 10-4 torr (6.7 x 10-4 mbar) | |

| Minimum | 1 x 10-8 torr (1.33 x 10-8 mbar) | |

| Beam characteristics | ||

| Beam deflection | 270° | |

| Beam spot size/shape | From tight oval to diffuse oblong | |

| Sweep capability | Longitudinal and lateral | |

| Evaporation rate | See chart below | |

| Installation requirements | ||

| Input power requirements | ||

| Filament current | 70 A at 12 V ac | |

| Emission current | 0–1.5 A at 4–10 kV dc (10 kW max.) | |

| Cooling water | ||

| Max. temperature | 68° F (20° C) | |

| Flow rate | 3.0 gpm (0.19 l/sec.) | |

| Max. inlet pressure | 100 psi (6.89 bar) | |

| Min. delta pressure | 50 psi (3.45 bar) | |

| Feedthroughs | ||

| High voltage | Two HV feedthroughs rated for 12 kV at 70 A | |

| Octal | One octal feedthrough rated for 110 V at 3 A per lead | |

| Dual pass | One dual-pass feedthrough with 3/8-in. (9.5-mm) OD tubes | |

| Rotary | One rotary-motion feedthrough with 1/4-in. (6.4-mm) dia. Shaft |

Model 2PT dimensions

Model 2PT dimensions

Representative deposition rates

The chart below shows deposition rates obtained using Temescal sources such as the 2PT and the 3PT. Consult Temescal for detailed information about how deposition rate and uniformity are affected by source operating volt age, beam sweep and density, and other fundamental process variables.

Deposition Rates of Various Materials from Temescal sources*

*25-cc pockets used in all tests. Source-to-substrate distance: 250 mm

When ordering a Temescal e-gun, you need to follow this process:

Step 1

Specify a source

Step 2

Specify a crucible

Step 3

Specify a crucible cover

For each source you wish to order, you must select part numbers for:

- A base unit

- An emitter

- A spare parts kit

After selecting your source, crucible and cover, please select any accessories that you would like to add to your order.

3PT PopTop source—base unit, emitter, spare parts kit

3PT PopTop source—crucible

3PT PopTop source—crucible cover

Items to be included in your quote request

2PT PopTop source—base unit, emitter, spare parts Kit

2PT PopTop source—crucible

2PT PopTop source—crucible cover

Items to be included in your quote request

PopTop accessories

-

Feedthrough Kit for 3CK PopTop

Read more -

Feedthrough Kit for 2CK PopTop

Read more -

Electrical Kit for the poptop

Read more -

Air Kit for the poptop

Add to cart