A Complete Family of Coating Systems

Our newly designed family of coaters offer solutions to processing requirements that range from small scale R&D or preproduction applications to large scale, high volume production fabrication lines. Ideal for either lift off or step coverage processes, these cleanroom compatible systems accept a multitude of accessories to meet almost any requirement.

In addition, our coaters are designed to optimize flexibility and efficiency in installation as well as operation. Fully automated processing via the Temescal control system maximizes throughput as well as ease of use. The PLC Based TCS provides fully integrated process and vacuum control, recipe driven pump to vent processing with datalogging, and automated pump, vent, and regeneration cycles that run independently of recipe processing.

A Temescal system is a production tool, designed for maximum efficiency, high throughput precision coating. This guiding philosophy dictates many of the system design decisions that run through our entire product line.

Auratus Technology

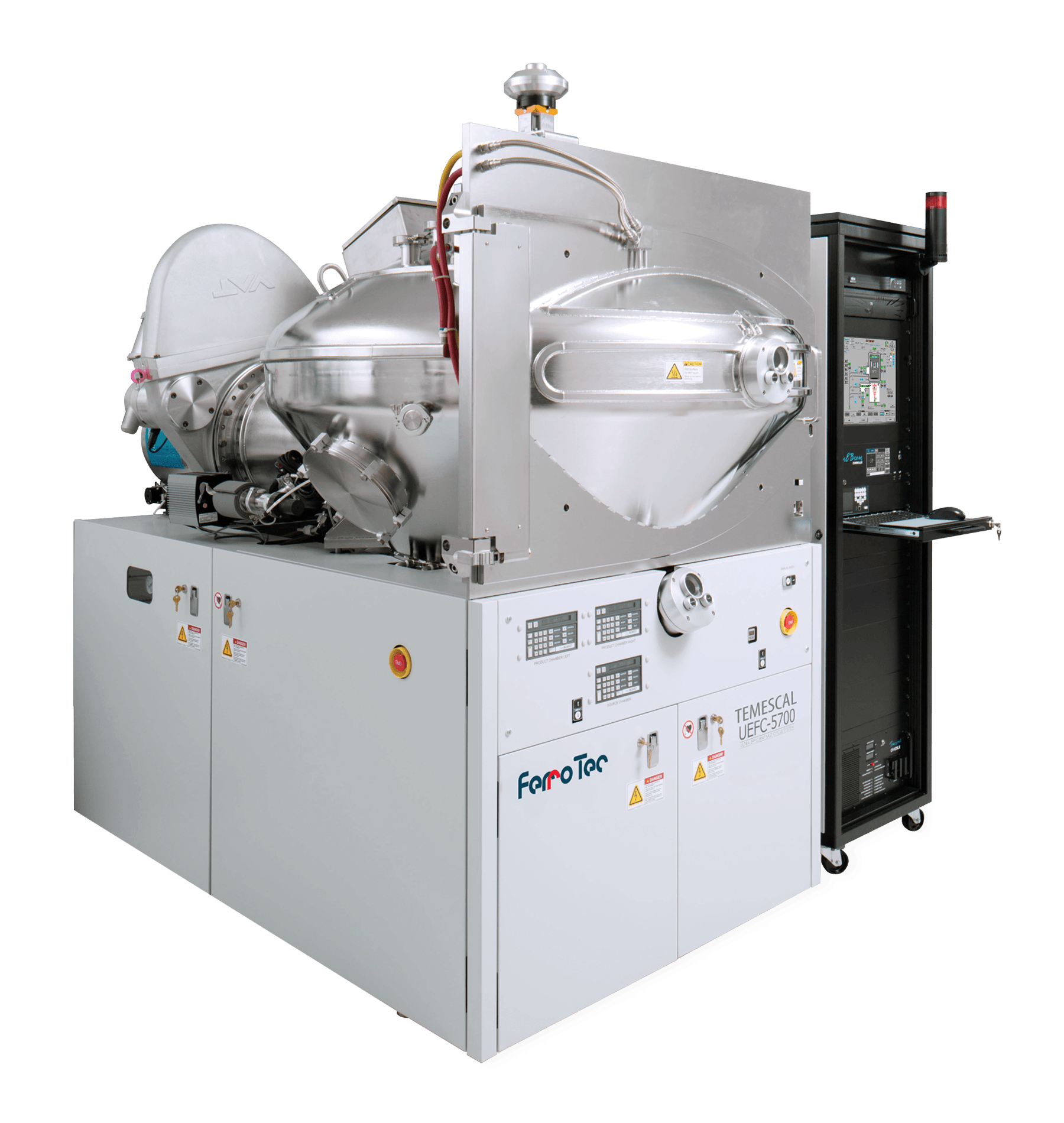

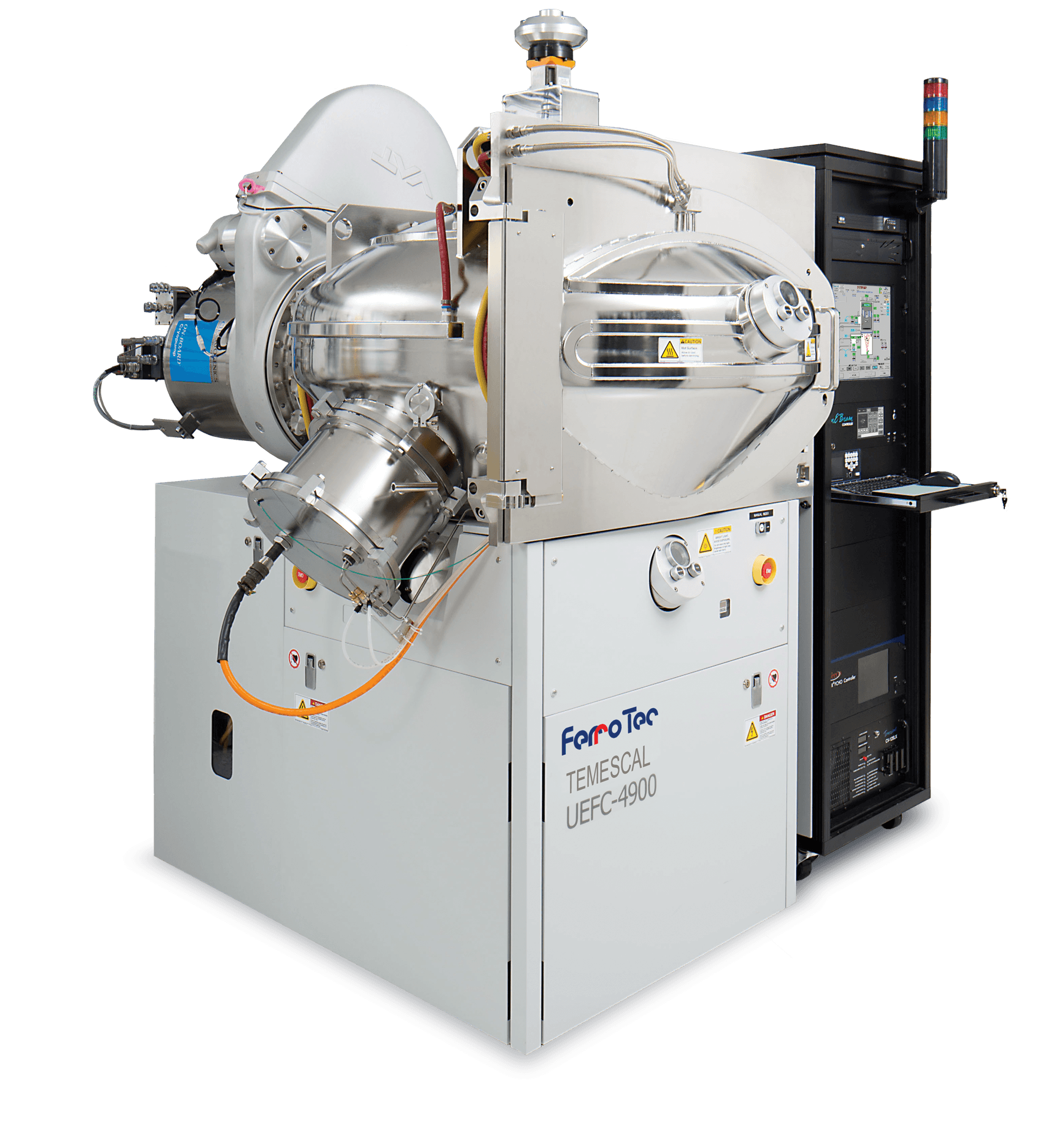

| Ultra-High throughput, large-wafer production, coating system | Ultimate, mid-sized, large-wafer production, coating system | ||

|---|---|---|---|

| System |  UEFC-5700 |

FC-4900 |

|

| Application |

Ultimate Uniformity Production: 150 & 200mm |

Ultimate Uniformity Production: 150mm |

|

| Product Chamber Type | Conic | Conic | |

| Load Lock to isolate Product Chamber | Yes | Yes | |

| Cryopump water L/sec | 44,000 | 36,500 | |

| Pump down time: |

1E-06 < 10mins |

1E-06 < 10mins |

|

| E-gun (max pkg) | 2 6 x 25cc PopTops + 1 fixed pocket | 2 6 x 25cc PopTops + 1 fixed pocket | |

| E-gun Power Supply | 6, 12, or 15 kW | 6, 12, or 15 kW | |

| Ion gun | MKII HC | MKII HC | |

| Max wafer count: Lift off | 42 x 150mm, 21 x 200mm | 25 x 150mm | |

| Source to Substrate: std | 43" | 35.5" | |

| Source to Substrate: ext | |||

| Learn more | Learn more | ||

| Learn about Auratus | Learn about Auratus | ||

Temescal Classic Technology

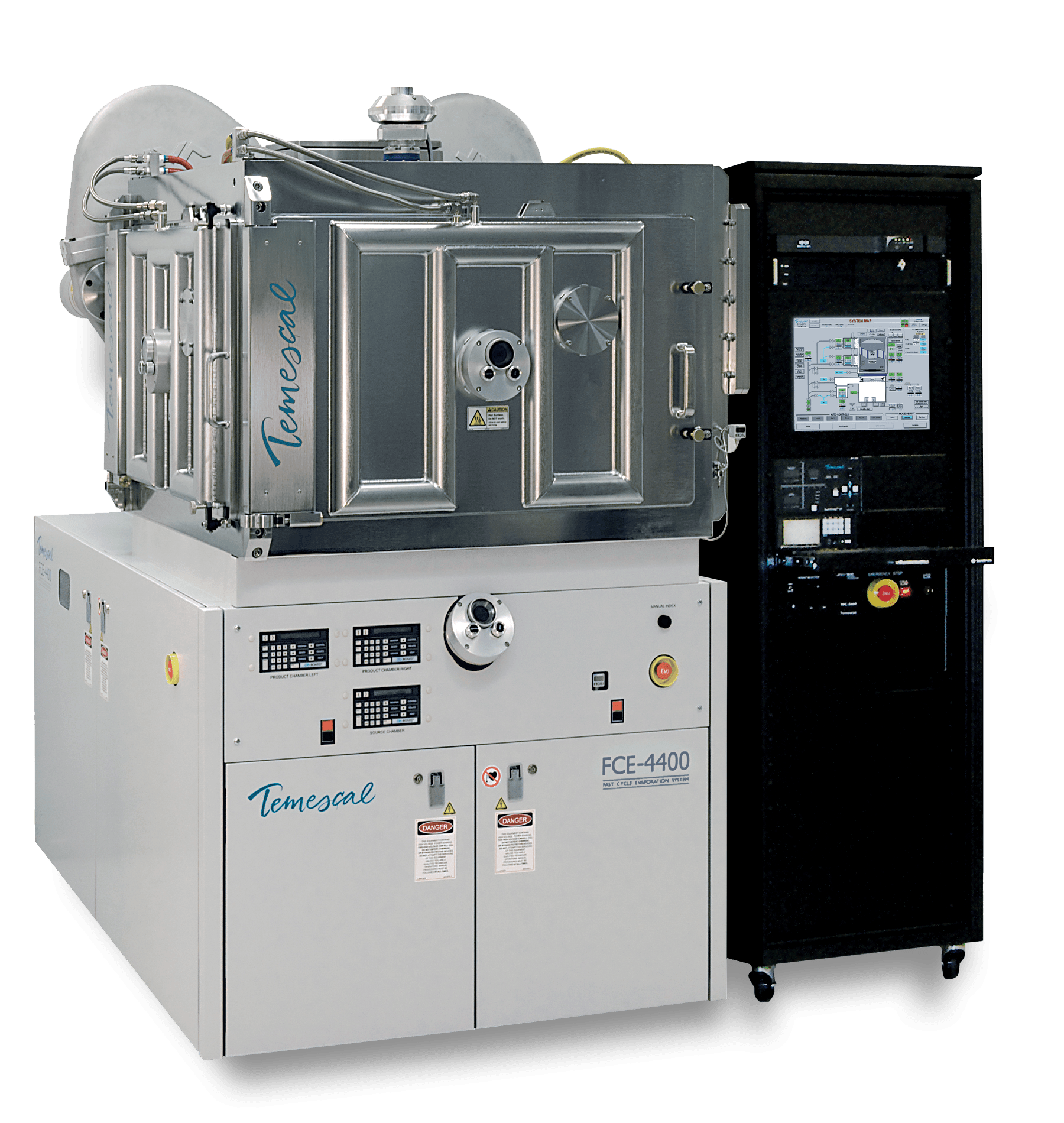

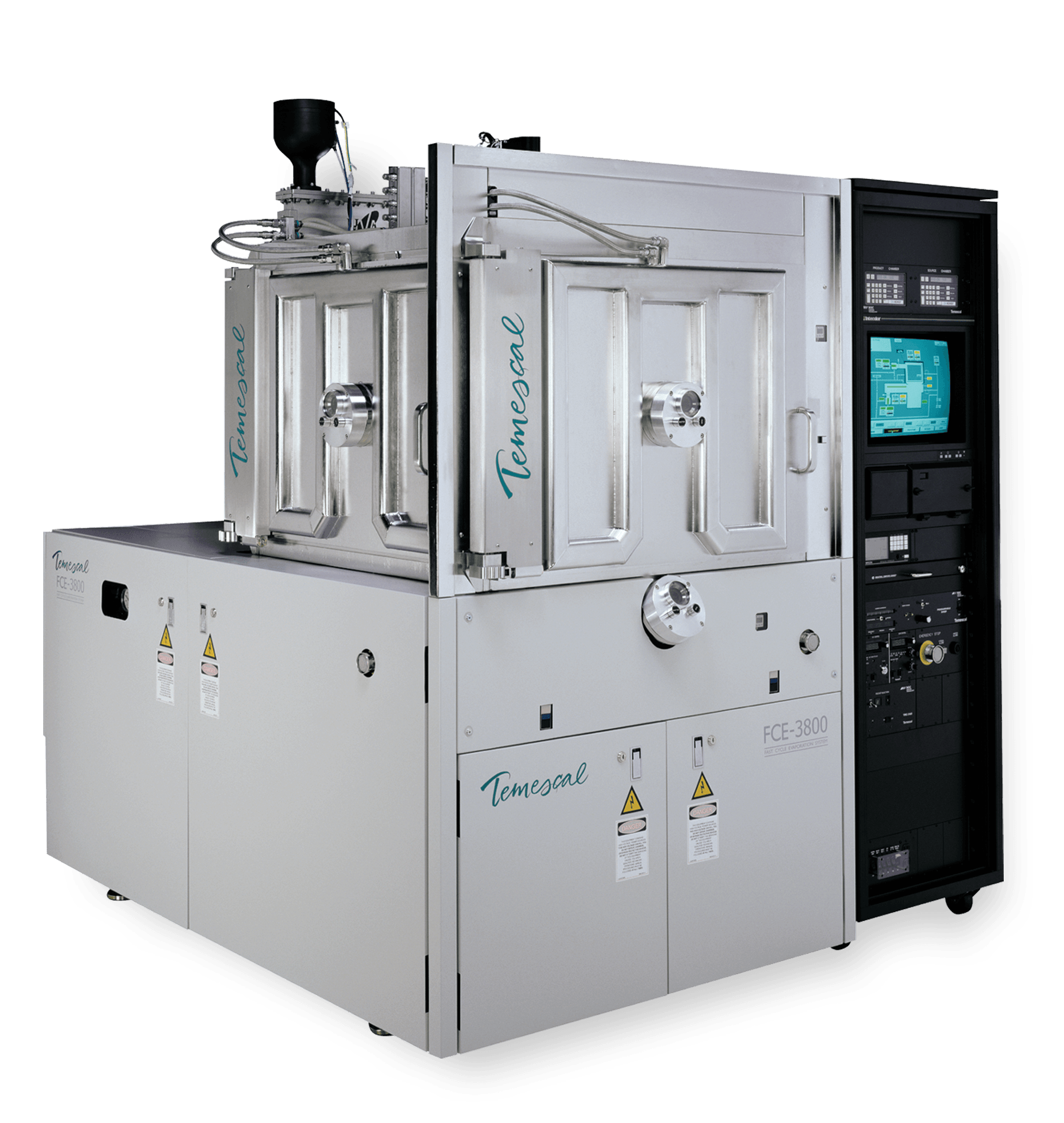

| High-Throughput, large-Wafer production coating systems | Mid-sized coaters for production and large-wafer R&D applications | Convertible bell jar systems for small-scale production and R&D applications | ||

|---|---|---|---|---|

| System: |  FC-4400 |

FC-3800 |

FC/BCD-2800 |

FC/BJD-2000 |

| Application |

Production: 150 & 200mm |

Production: 100mm | University, R&D, Pilot Production | University, R&D, Pilot Production |

| Product Chamber Type | Box | Box | Box | Bell jar |

| Load Lock to isolate Product Chamber | Yes | Yes | Yes | |

| Cryopump water L/sec | 44,000 | 21,500 | 21,500 | 4,000 |

| Pump down time: |

1E-06 < 10mins |

1E-06 < 20mins |

1E-06 < 20mins |

1E-06 < 15mins |

| E-gun (max pkg) | 2 6 x 25cc PopTops + 1 fixed pocket | 4 x 25cc PopTop + 1 fixed pocket | 4 x 25cc PopTop + 1 fixed pocket | 4 x 25cc PopTop + 1 fixed pocket |

| E-gun Power Supply | 6, 12, or 15 kW | 6 or 12 kW | 6 or 12 kW | 6 or 12 kW |

| Ion gun | MKII HC | MKII filament | MKII filament | MKI filament |

| Max wafer count: Lift off | 30 x 150mm, 15 x 200mm | 25 x 150mm, 14 x 200mm | 25 x 100mm, 12 x 150mm | 42 x 2", 13 x 100mm |

| Source to Substrate: std | 38" | 34" | 34" | 19.5" |

| Source to Substrate: ext | 42" | 38" | 42" | 27.5" |

| Learn more | Learn more | Learn more | Learn more | |