Embrace The Cloud—A Better Way To Optimize Your Lift-Off Coating Process

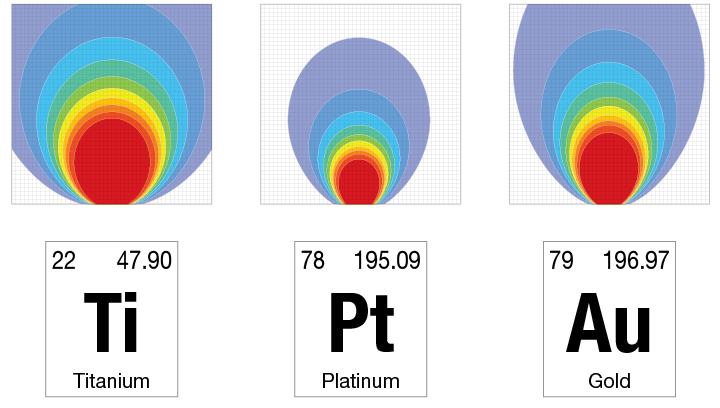

At the heart of every electron beam evaporation system is a vapor cloud—a unique, repeatable flux distribution characteristic of radiation from a point source.

But these flux clouds can vary. They change because of a variety of factors in the deposition process—like deposition material, deposition power, crucible size, the use of a crucible liner and beam spot focus.

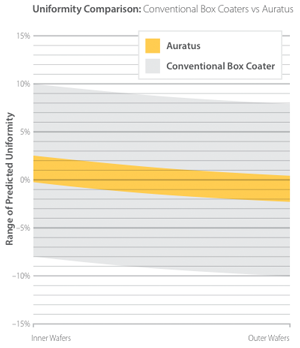

With precision lift-off coating, the goal is an even, predictable deposition layer across a batch of wafers. Uniformity masks are the conventional solution for managing the flux cloud, trimming the heaviest zones of deposition to match that of the least flux zones’ collection.

On a conventional box coater, an inefficient optimization to the flux cloud typically results in an excessive use of process metals. And with so many variables, how do you design an optimal mask?

For over a decade, Temescal has been dedicated to mapping and better understanding the dynamics of the flux cloud. Through extensive testing and research, we have collected hundreds of vapor cloud maps and used these maps to advance and automate the process of lift-off uniformity mask design.

One Day, We Imagined a Better Way…

Auratus is a proprietary optimization methodology for lift-off electron beam evaporative coating that incorporates patent pending technology to achieve unprecedented levels of uniformity, precision, and collection efficiency. Auratus enables Temescal customers to coat wafers with near perfect uniformity, resulting in more consistent, better quality products and fewer defects. Temescal’s Auratus methodology also has the capability to increase the effective deposition rate, enabling customers to increase throughput.

Unprecedented Uniformity

The Auratus deposition process enhancement methodology coats wafers with near perfect uniformity, resulting in more consistent, better quality products and fewer defects.

Eliminating the need for developing new uniformity masks for each process layer also speeds up production time.

Dramatic Savings

With lift-off metallization coating processes on a conventional box coater, an inefficient optimization to the flux cloud typically results in an excessive use of process metals. In addition to the material that get’s deposited on the wafers, process metals also get dispersed throughout the chamber. You can recover some of that through system service and recycling, but you can’t reclaim all of it. It’s like you’re vaporizing money.

Our revolutionary process enhancement methodology gives you significant reductions in material consumption. For evaporants such as gold and platinum, this can mean savings of up to 40% in material costs.