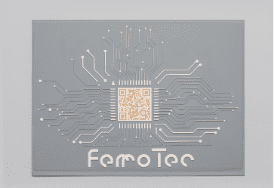

Power Electronic

DBC & AMB Substrates

For insulating substrates and circuit substrates for heat release applying thermo-module manufacturing technology, many organic substrates and metallic substrates are generally used for low-power home electrical appliances and PCs, etc. As heat-release insulating substrates for power modules handling large amounts of power, alumina, aluminum nitride, and silicon nitride substrates are used.

Especially for the power module of an inverter / converter upon the increase of the sales volume of HEV and EV, silicon nitride substrates have attracted attention. Our company started the mass production of new products, AMB (Active Metal Brazing) substrates in addition to the existing products, DBC (Direct Bond Copper) substrates.

This product contributing to downsizing and energy saving is expected to grow in the future.

Product Line

| DBC Substrate properties | ||||

|---|---|---|---|---|

| DBC Substrate | Item | Value | Unit | |

| Master Card Size(Max) | 138*190 | mm | ||

| Max.Useable area(Max) | 127*178 | mm | ||

| Sacing between SOLDERMASK pattern(Min) | Followed by design rule | mm | ||

| SOLDERMASK pattern width(Min) | +0.3/-0.2 | mm | ||

| Peeling Strength(Min) | >5 | N/mm | ||

| Solderability | >95% | % | ||

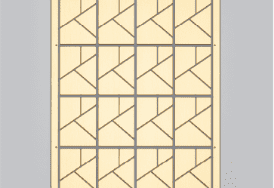

| Delivery Term | Single Pieces Delivery/Mastercard Delivery | |||

| Surface Options | Bare Copper/Solder Stop/Electronics Ni-Plating::2~8/ Electroless NiAu-Plating::2~8&0.01~0.1/Electroless Ag 0.1-0.6μm |

µm | ||

| Material | ZTA Ceramic | Content | 90% Al / ZrO₂ | % |

| Thickness | 0.32,0.25 | mm | ||

| Density | 3.95 | g/cm³ | ||

| Thermal Conductivity | 27 | W/m.k | ||

| Bending Strength | 600 | W/m.k | ||

| Dielectric Constant | 10.5 | 1MHz | ||

| Dielectric Loss | 0.0003 | 1MHz | ||

| Dielectric Strength | 20 | kV/mm | ||

| Electrical Resistivity | 1*1014 | Ωcm | ||

| Al2O3 Ceramic | Content | 96% Al₂O₃ | % | |

| Thickness | 1.00,0.89,0.76,0.63,0.5,0.3 8,0.32,0.25 | mm | ||

| Density | 3.73 | g/cm³ | ||

| Thermal Conductivity | 24 | W/m.k | ||

| Bending Strength | 350~450 | Mpa | ||

| Dielectric Constant | 9.8 | 1MHz | ||

| Dielectric Loss | 0.0003 | 1MHz | ||

| Dielectric Strength | 20 | kV/mm | ||

| Electrical Resistivity | 1*1014 | Ωcm | ||

| Copper | Material | OFHC | % | |

| Purity | 99.99 | % | ||

| Hardness | 90~110 | HV | ||

| Electrical Conductivity | 58.6 | MS/m | ||

| Copper Thickness | 0.40,0.30,0.25,0.20,0.127 | mm | ||

AMB

Active Metal Brazing

| AMB Substrate properties | ||||

|---|---|---|---|---|

| AMB Substrate | Item | Value | Unit | |

| Master Card Size(Max) | 138*190 | mm | ||

| Max.Useable area(Max) | 127*178 | mm | ||

| Sacing between SOLDERMASK pattern(Min) | Followed by design rule | mm | ||

| SOLDERMASK pattern width(Min) | +0.3/-0.2 | mm | ||

| Peeling Strength(Min) | >10 | N/mm | ||

| Solderability | >95% | % | ||

| Delivery Term | Single Pieces Delivery/Mastercard Delivery | |||

| Surface Options | Bare Copper/Solder Stop/Electronics Ni-Plating::2~8/ Electroless NiAu-Plating:2~8&0.01~0.1/Electroless Ag 0.1-0.6μm |

µm | ||

| Material | SiN Ceramic | SiN Content | 96% SiN | % |

| Thickness | 0.32,0.25 | mm | ||

| Density | 3.22 | g/cm³ | ||

| Thermal Conductivity | 90 | W/m.k | ||

| Bending Strength | 700 | Mpa | ||

| Dielectric Constant | 8 | 1MHz | ||

| Dielectric Loss | 0.001 | 1MHz | ||

| Dielectric Strength | 20 | kV/mm | ||

| Electrical Resistivity | 1*1014 | Ωcm | ||

| AlN Ceramic | Content | 96% AlN | % | |

| Thickness | 1.0,0.63,0.38,0.25 | mm | ||

| Density | 3.3 | g/cm³ | ||

| Thermal Conductivity | 170 | W/m.k | ||

| Bending Strength | 350 | Mpa | ||

| Dielectric Constant | 9 | 1MHz | ||

| Dielectric Loss | 0.0005 | 1MHz | ||

| Dielectric Strength | 20 | kV/mm | ||

| Electrical Resistivity | 1*1014 | Ωcm | ||

| Copper | Material | OFHC | ||

| Purity | 99.99 | % | ||

| Hardness | 60~110 | HV | ||

| Electrical Conductivity | 58.6 | MS/m | ||

| Copper Thickness | 0.8,0.5,0.4,0.3,0.25,0.2 | mm | ||

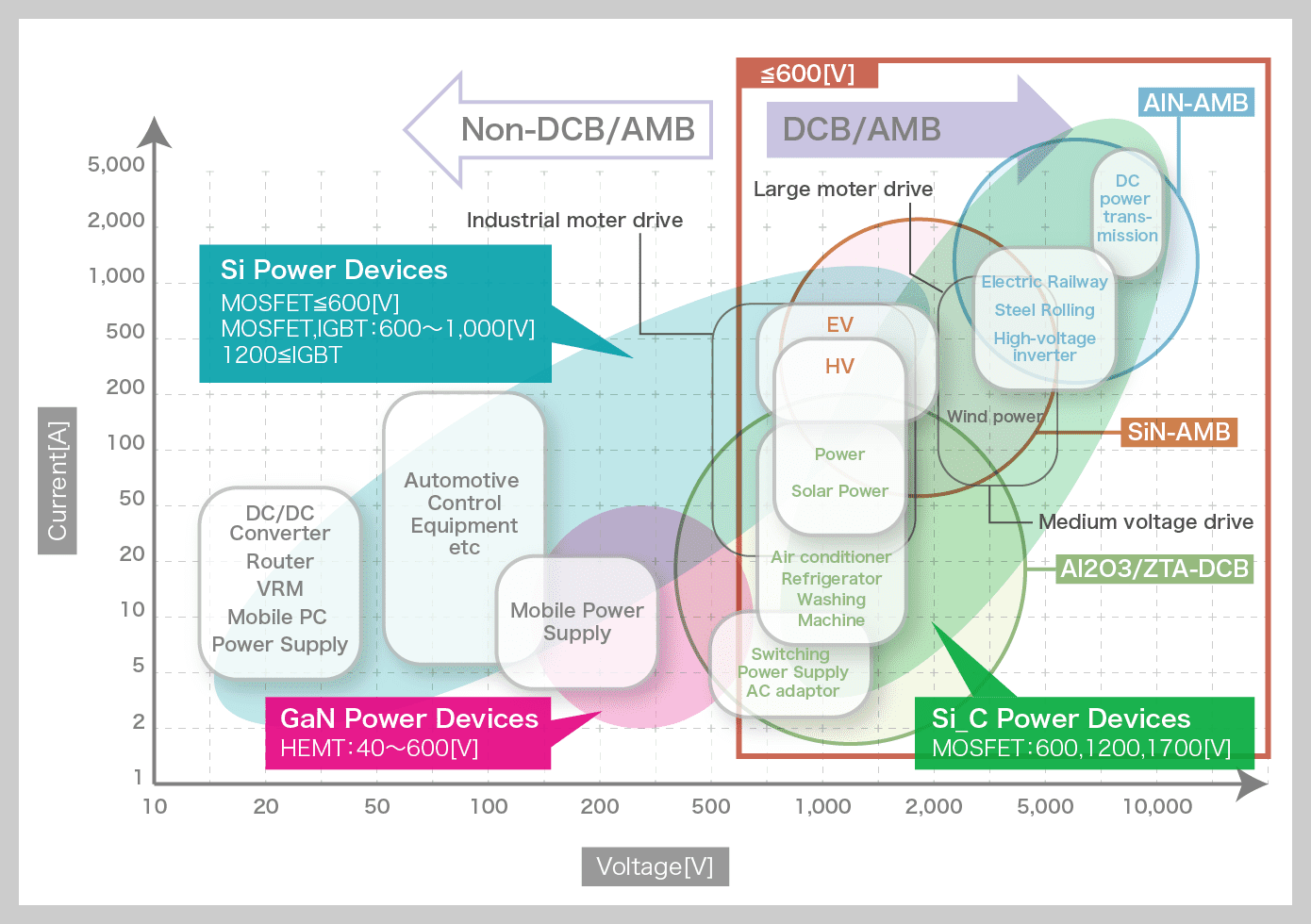

Types, withstanding pressure, and use application of power electronic substrates

Main market range of DBC/AMB: industrial equipment, vehicle, electric railway, recyclable energy