- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Semiconductor Equipment RelatedEB Components

- Electronic Device RelatedFerrofluid

EB Components

E-Beam Controllers

China Advanced Ceramic E-Beam Controllers

China Advanced Ceramic offers electron beam controllers for use with specific power supply models.

Genius2 EBC Integrated Controller

Eliminate Complexity and Simplify Your Electron Beam Control System

The Genius2 Multi-function Integrated Electron Beam Controller, a unique new component-level solution for simplifying electron beam systems. With the Genius2 controller you can consolidate components, reduce costs and simplify management of common functionality though a unified interface. The Genius2 controller is designed to work with integrated feedthrough e-guns and Carrera series power supplies.

Multi-function Integrated Controller

Simplify your system with one 19” rack-mount unit and eliminate the need for discrete control components.

- E-Beam controller

- High voltage power supply controller

- Sweep controller

- Turret controller

Simplified Operator Interface

Make it easier for operators to run your e-beam system.

- Multiple control systems managed through a single touch screen interface

- Access basic operating information through the easy-to-read home screen

- Basic control adjustments can be made with a couple of clicks

- Identify and correct complex system errors from single screen

- Enjoy “at-a-distance” operation using the convenient hand-held universal remote

Lower Your Component Cost

China Advanced Ceramic Genius2 EBC integrated controller offers a substantial savings versus the cost of discrete devices.

- Save money purchasing one integrated system instead of a rack full of discrete components

- Reduce your component operating power consumption with one unit instead of four

Simplify Your System Wiring

Streamline your system with the EBC and eliminate tangled wires and spaghetti interconnects.

- All controller wiring routes to a single component

- Eliminate legacy wiring and connections between controllers

OEM ready

China Advanced Ceramic Genius2 EBC platform is designed for streamlined integration into PLC environments.

Genius E-Beam Controllers

Regulates All Aspects of the Electron Beam Deposition Process

The programmable Genius deposition controller regulates all aspects of the electron beam deposition process. As well as controlling the high voltage and regulating the filament supply, the Genius also handles the magnet current supply to the coils of the electron beam evaporator.

All of the Genius functions are included on the remote control which can be used to manually set and control the evaporation process as well as to set all process and system parameters.

Access to the menu functions may be limited with three password protected user levels.

In order to achieve the best in film quality and uniform evaporant utilization, the Genius can store a wide variety of evaporation parameters. Different data sets can then be applied to different phases of the process (eg. material melting and various coating phases). In addition to storing various beam sweep parameters, different high voltage values may also be set.

The Genius, when used with a Carrera series power supply, allows up to three electron beam sources to be run from a single power supply.

Regulates All Aspects of the Electron Beam Deposition Process

The programmable Genius deposition controller regulates all aspects of the electron beam deposition process. As well as controlling the high voltage and regulating the filament supply, the Genius also handles the magnet current supply to the coils of the electron beam evaporator.

All of the Genius functions are included on the remote control which can be used to manually set and control the evaporation process as well as to set all process and system parameters.

Access to the menu functions may be limited with three password protected user levels.

In order to achieve the best in film quality and uniform evaporant utilization, the Genius can store a wide variety of evaporation parameters. Different data sets can then be applied to different phases of the process (eg. material melting and various coating phases). In addition to storing various beam sweep parameters, different high voltage values may also be set.

The Genius, when used with a Carrera series power supply, allows up to three electron beam sources to be run from a single power supply.

There are 2 Configurations:

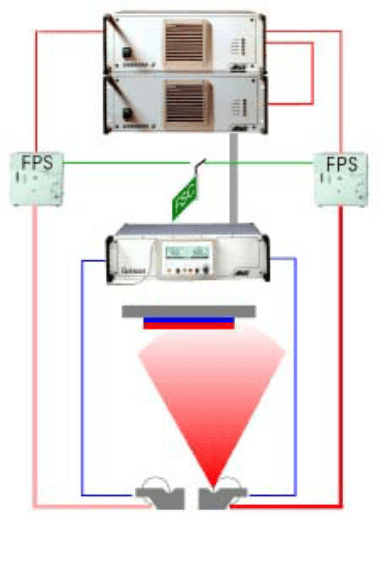

Sequential Deposition

A filament switch card can be fitted to the Genius, enabling selection and deposition from one of several evaporators within the vacuum chamber. In this configuration, each evaporator requires a dedicated filament power supply.

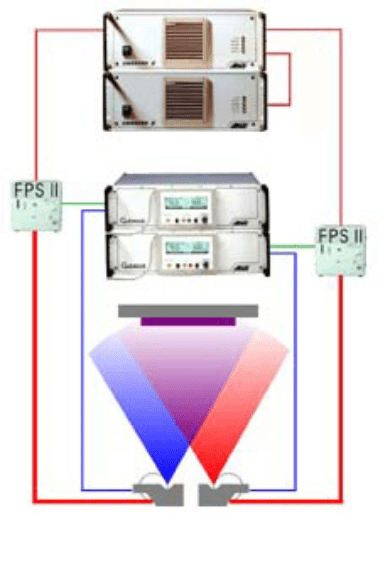

Simultaneous Deposition

For simultaneous evaporation from several electron beam evaporators, each source is driven by its own individual Genius unit. In this configuration, the evaporators can be powered from a single Carrera high voltage power supply because the emission current is directly recorded by the filament power supply FPS-II.